Common PCB Design Steps

Published on 7/24/2019 2:56:21 PM

Description

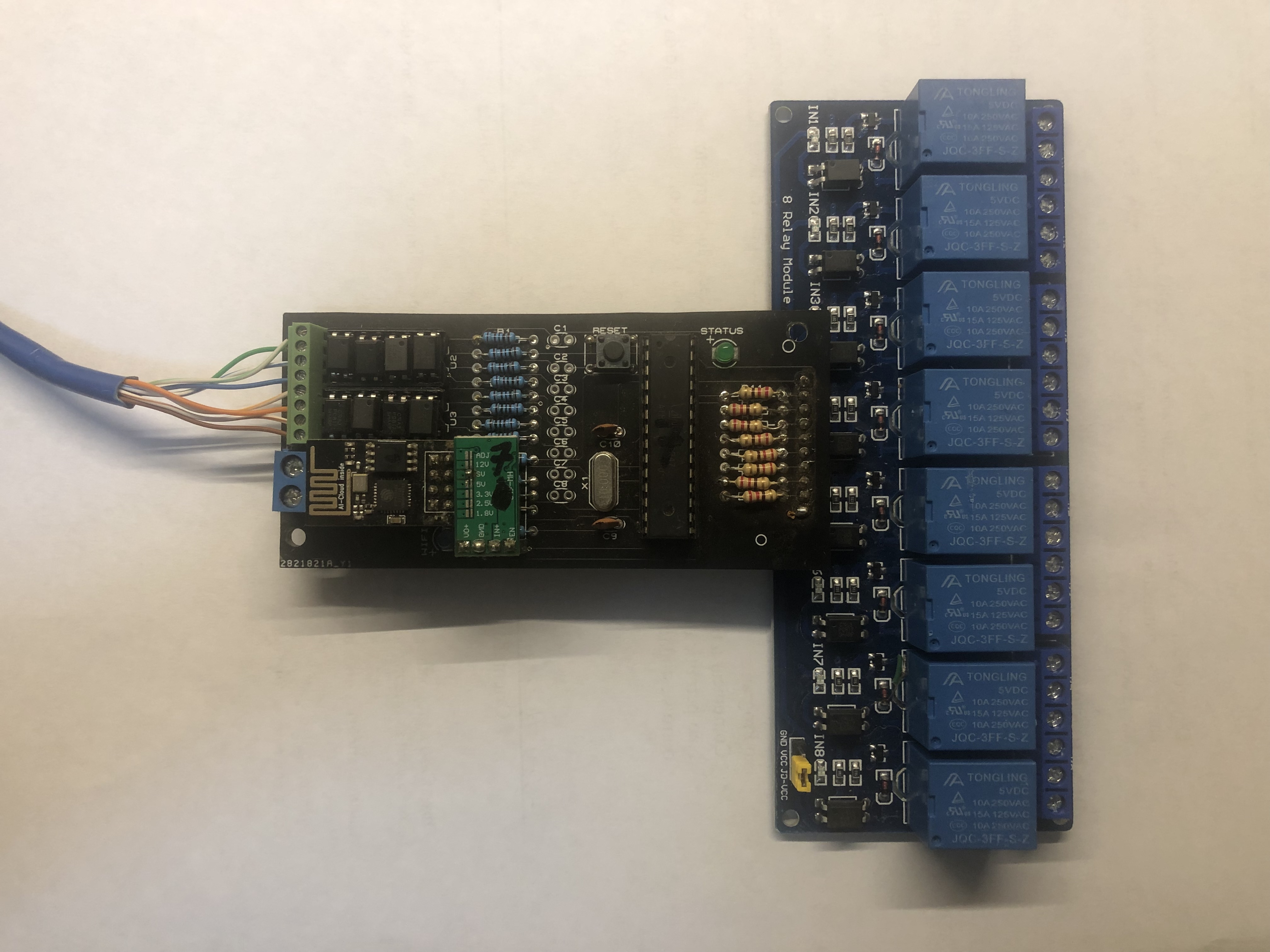

<p style="text-indent: 0em; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">In this essay, we will have brief introduction of the common <strong>PCB design</strong> steps.</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; line-height: 1.5em;"><strong><span style="font-size: 16px; font-family: Helvetica;">Preliminary preparation</span></strong></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="text-indent: 0px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Clearly design the target, select the selected device type, confirm the overall plan, and come up with a written design plan.</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"><br/></span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Prepare the schematic package library and PCB package library of the device. There is specific package information for every component. If there is no such thing in the base library, it must be searched from the Internet. If it is still not available, it can only be drawn by itself. Some package generation software can be used to do this. It should be noted that the package must be placed in the specified directory;</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; text-align: center; line-height: 1.5em;"><img src="https://jpfile1.oss-cn-shenzhen.aliyuncs.com/allpcb/web/image/20190724/6369957685992493837409349.jpg" alt="the schematic package library.jpg"/><span style="font-size: 16px; font-family: Helvetica;"></span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; line-height: 1.5em;"><strong><span style="font-size: 16px; font-family: Helvetica;">PCB design</span></strong></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">This part is the main part of the board design, but if there are problems in the previous scheme, it will bring a lot of obstacles to the back, so a good solution is half successful. The next step is to design step by step.</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">1. Schematic design</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">The workload of schematic design is not very large, but the importance is undoubtedly a correct schematic is the guarantee of the entire board function;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">2. Create a schematic netlist</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">After the schematic is drawn, the netlist is generated and used for later import into the PCB drawing software. If cadence is used, the generated netlist file contains three files: pstxnet.dat/ pstxprt.dat/ pstchip.dat;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">3. Create a mechanical design</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Set related information such as PCB frame and height limit, and generate new mechanical drawing files and save them to the specified directory;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">4. Read schematic net list</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Read the schematic net list into PCB software such as Allegro;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">5. Set basic information of the PCB board</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Before starting layout and routing, you must first set the board layer, grid spacing, color and design constraints of the PCB board;</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; text-align: center; line-height: 1.5em;"><img src="https://jpfile1.oss-cn-shenzhen.aliyuncs.com/allpcb/web/image/20190724/6369957689095347353301253.jpg" alt="Set basic information of the PCB board.jpg"/><span style="font-size: 16px; font-family: Helvetica;"></span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">6. PCB layout</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">In addition to the very simple schematic, it is recommended to make a reasonable manual layout according to the functional distribution of the schematic. Manual wiring takes a long time, but it is more detailed and meets the actual requirements; automatic routing speed is fast but more over-control is used. It is generally recommended to manually route or combine the two methods;</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 32px; text-align: center; line-height: 1.5em;"><img src="https://jpfile1.oss-cn-shenzhen.aliyuncs.com/allpcb/web/image/20190724/6369957690599994972704576.jpg" alt="pcb layout.jpg"/><span style="font-size: 16px; font-family: Helvetica;"></span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">7. Place test points</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Place some voltage test points in the appropriate position to facilitate quick test confirmation after the board is fabricated;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">8. Copper plating on the top and bottom</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">This step is not required, but almost all mature designs will be carried out. This not only strengthens the circuit board, prevents war page, but also enhances the shielding performance of the PCB board and improves the anti-interference ability of the PCB board;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">9. Constraint rule checking</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">If some constraint rules are designed before the layout and routing, at this time, it is necessary to enter the constraint table for inspection, and whether all the routing designs are in compliance with the rules;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="text-indent: 0px; line-height: 1.5em;"><strong><span style="font-size: 16px; font-family: Helvetica;">Post processing work</span></strong></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">1. Adjust the board text</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Add and adjust the silkscreen, and add some necessary information and company logo on the board;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">2. Output illuminating files</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Generate the correct illuminating file, you can use it to send the plate-making manufacturer for processing;</span></p><p style="text-indent: 32px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;"> </span></p><p style="margin-left: 0px; text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">3. Document archiving</span></p><p style="text-indent: 0px; line-height: 1.5em;"><span style="font-size: 16px; font-family: Helvetica;">Commonly used reports are: component list, circuit board interface wiring table, printed circuit schematic and PCB board diagram.</span></p><p style="text-indent: 0px;"><br/></p>

63

comment

All comments

Adrian Wellings

Adrian Wellings

5839

0

63

Rules about cashback: 1. Valid time: ALLPCB cashback activity will end on April 1st. 2. Capped amount: The capped amount of cashback for each account is $5,000. Each order can get a maximum of $2,000 cashback. That means every author can get $5,000 max. 3. Cashback range: The cashback activity only covers the corresponding PCB order. The order amount for other combined payment products will be invalid. 4. Clicking your own promotional link will be invalid. The same email address, shipping address, contact information, and phone number are all recognized as the same account. 5. ALLPCB has the final interpretation right of the cashback activity.

ALLPCB will donate 2% to the author for this promotion link.