PCB Copper Coating Experience

Published on 12/27/2018 2:01:52 PM

Description

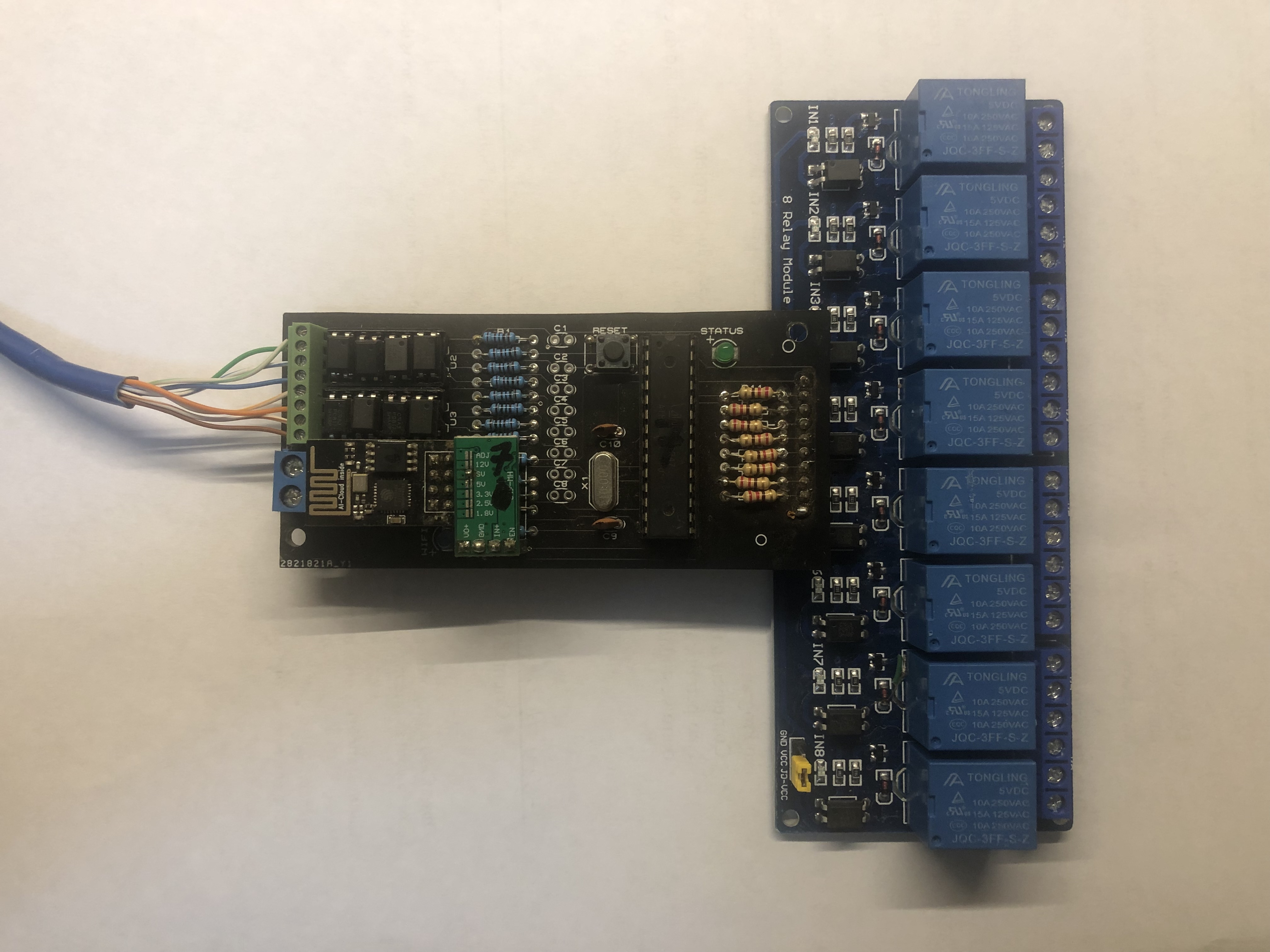

<p style="margin:0pt;"><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="font-family:"font-size:18px;"><span style="font-family:"font-size:16px;">The so-called </span><strong><span style="font-family:"font-size:16px;">copper coating</span></strong><span style="font-family:"font-size:16px;"> is to use the unused space on the PCB as the reference surface, and then fill it with</span><a href="https://www.allpcb.com/pcb_design/copper_cladding.html" target="_blank"> </a></span><strong><span style="font-family:"font-size:18px;"><a href="https://www.allpcb.com/pcb_design/copper_cladding.html" target="_blank"><span style="font-family:"font-size:16px;">solid copper</span></a></span></strong><span style="font-family:"font-size:16px;">, which is also called copper filling. The significance of </span><strong><a href="https://www.allpcb.com/pcb_design/copper_cladding.html" target="_blank"><span style="font-family:"font-size:16px;">copper coating</span></a> </strong><span style="font-family:"font-size:16px;"> is to reduce the ground line impedance, improve the anti-interference ability; reduce the voltage drop and improve the power supply efficiency; and, connect with the ground line to reduce the loop area.</span></span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><!--?xml:namespace prefix = o ns = "urn:schemas-microsoft-com:office:office" /--></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">If the PCB has more ground, there are </span><span style="font-family:"font-size:16px;">often named as </span><span style="font-family:"font-size:16px;">GND</span><span style="font-family:"font-size:16px;">, </span><span style="font-family:"font-size:16px;">SGND,</span><span style="font-family:"font-size:16px;"> which are</span><span style="font-family:"font-size:16px;"> depending on the </span><span style="font-family:"font-size:16px;">places in </span><span style="font-family:"font-size:16px;">the PCB surface,</span><span style="font-family:"font-size:16px;"> and for</span><span style="font-family:"font-size:16px;"> the main "ground" </span><span style="font-family:"font-size:16px;">, it </span><span style="font-family:"font-size:16px;">is used to separate the copper, and the digital ground and the analog ground.</span> </p><p style="margin:0pt;"><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">B</span><span style="font-family:"font-size:16px;">efore</span><span style="font-family:"font-size:16px;"> </span><span style="font-family:"font-size:16px;">coating</span><span style="font-family:"font-size:16px;"> the </span><span style="font-family:"font-size:16px;">copper, </span><span style="font-family:"font-size:16px;">the </span><span style="font-family:"font-size:16px;">first</span><span style="font-family:"font-size:16px;"> step is </span><span style="font-family:"font-size:16px;">needed</span><span style="font-family:"font-size:16px;"> to </span><span style="font-family:"font-size:16px;">increase the corresponding</span><span style="font-family:"font-size:16px;"> for</span><span style="font-family:"font-size:16px;"> power connection: 5.0V, 3.3V and so on. In this way, a plurality of multi-deformed structures of different shapes </span><span style="font-family:"font-size:16px;">will be </span><span style="font-family:"font-size:16px;">formed.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="text-align:center;margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="text-align:center;margin:0pt;"><span style="font-family:"font-size:18px;"><br/></span> </p><p style="text-align:center;margin:0pt;"><span style="font-family:"font-size:18px;"><img src="https://file.allpcb.com/bbs/18/12/28/154952670.jpg" alt=""/></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:18px;"><strong><span style="font-family:"font-size:16px;">Copper clad</span></strong><span style="font-family:"font-size:16px;"> needs to deal with several problems: First, a single point connection in different places, the method is to connect through 0 ohm resistor or magnetic beads or inductor; second is copper clad in the vicinity of crystal oscillator, the crystal oscillator in the circuit is a high frequency emission source, The copper is applied around the crystal, and then the outer casing of the crystal is grounded separately. The third is the problem of an isolated island (dead zone). If you feel that it is very big, it will not cost much to define a place to add it.</span></span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:18px;"><span style="font-family:"font-size:16px;">In addition, the large area of copper is good or the grid is copper, it is not easy to generalize. Why? Large area copper clad, if the<a href="https://www.allpcb.com/sns/how-flexible-board-are-manufactured_26249.html" target="_self" title="How Flexible Board Are Manufactured?"> wave soldering</a>, the board may be tilted up, and even foaming. From this point of view, the </span><strong><span style="font-family:"font-size:16px;">heat dissipation</span></strong><span style="font-family:"font-size:16px;"> of the grid is better. Usually, the high-frequency circuit is used to resist the interference of the multi-purpose grid, and the low-frequency circuit has a large current circuit and the like.</span></span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="text-align:center;margin:0pt;"><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><img src="https://file.allpcb.com/bbs/18/12/28/155022991.jpg" alt=""/><span style="font-family:"font-size:16px;"> </span></span> </p><p style="margin:0pt;"><br/></p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">When starting the wiring, the ground wire should be treated equally. When the wire is routed, the ground wire should be taken well. It is not possible to rely on the copper to add the hole to eliminate the ground pin. This effect is very bad. Of course, if you choose the grid copper, these ground connections will affect the appearance, if you are careful, delete it.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">1. Large area of</span><span style="font-family:"font-size:16px;"> </span><span style="font-family:"font-size:16px;">copper is applied, which has the dual functions of increasing current and shielding. The simple grid copper is mainly shielded, and the effect of increasing current is reduced. The purpose of adding grid is not necessarily for beauty, but Prevent and alleviates the gas generated when the copper foil adhesive is welded to foam the copper foil. Therefore, it is a large area of</span><span style="font-family:"font-size:16px;"> </span><span style="font-family:"font-size:16px;">copper, and also pay attention to open a few grooves to ease the foaming of the copper foil.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">2</span><span style="font-family:"font-size:16px;">.</span><span style="font-family:"font-size:16px;"> </span><span style="font-family:"font-size:16px;">T</span><span style="font-family:"font-size:16px;">he ring ground wire can have shielding effect; can also form the reception of the radiation signal</span><span style="font-family:"font-size:16px;"> that is s</span><span style="font-family:"font-size:16px;">imilar to the loop antenna. Therefore, the charger has both high current and small signal detection, so it is better to use "tree type ground wire. .</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">3. Such a general charging control IC is also connected to the ground loop and then connected to the high current ground loop to reduce the interference of the copper foil voltage drop of the large current loop on the small signal.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;">This is not absolute, you can also see a lot of violations of the above requirements, you can also use. But I will pay attention to these requirements as much as possible in the general layout.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><p style="margin:0pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:1em 0px 1em 18pt;text-indent:-18pt;mso-char-indent-count:0.0000;mso-list:l0 level1 lfo1;"><span style="font-family:"font-size:12pt;mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="mso-list:Ignore;"><span style="font-family:"font-size:16px;">1.</span><span style="font-family:"font-size:16px;"> </span></span></span><span style="font-family:"font-size:16px;">The wiring of the middle layer of the multi-layer board is not empty. Because it is very difficult for you to make this copper "good grounding".</span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span> </p><p style="margin:1em 0px 1em 18pt;text-indent:0pt;mso-char-indent-count:0.0000;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:1em 0px 1em 18pt;text-indent:-18pt;mso-char-indent-count:0.0000;mso-list:l0 level1 lfo1;"><span style="font-family:"font-size:12pt;mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="mso-list:Ignore;"><span style="font-family:"font-size:16px;">2.</span><span style="font-family:"font-size:16px;"> </span></span></span><span style="font-family:"font-size:16px;">A PCB, no matter how many kinds of power supply, it is recommended to use power split technology, and only use one power layer. Because the power supply is the same as the ground, it is also the “reference plane”. The “good grounding” of the power supply and the ground is realized by a large number of filter capacitors. Without the filter capacitor, there is no “ground”.</span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span> </p><p style="margin:1em 0px 1em 18pt;text-indent:0pt;mso-char-indent-count:0.0000;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:1em 0px 1em 18pt;text-indent:-18pt;mso-char-indent-count:0.0000;mso-list:l0 level1 lfo1;"><span style="font-family:"font-size:12pt;mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="mso-list:Ignore;"><span style="font-family:"font-size:16px;">3.</span><span style="font-family:"font-size:16px;"> </span></span></span><span style="font-family:"font-size:16px;">The metal inside the equipment, such as metal radiators, metal reinforcement strips, etc., must achieve "good grounding."</span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span> </p><p style="margin:1em 0px;text-indent:24pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin:1em 0px 1em 18pt;text-indent:-18pt;mso-char-indent-count:0.0000;mso-list:l0 level1 lfo1;"><span style="font-family:"font-size:12pt;mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="mso-list:Ignore;"><span style="font-family:"font-size:16px;">4.</span><span style="font-family:"font-size:16px;"> </span></span></span><span style="font-family:"font-size:16px;">The heat-dissipating metal block of the three-terminal regulator must be well grounded.</span><span style="font-family:宋体;font-size:12pt;mso-spacerun:"mso-font-kerning:1.0000pt;mso-bidi-font-family:"mso-ascii-font-family:"mso-hansi-font-family:""></span> </p><p style="margin:1em 0px;text-indent:24pt;"><span style="font-family:"font-size:16px;"> </span> </p><p style="margin: 1em 0px 1em 18pt; text-indent: -18pt;"><span style="font-family:"font-size:12pt;mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"><span style="mso-list:Ignore;"><span style="font-family:"font-size:16px;">5.</span><span style="font-family:"font-size:16px;"> </span></span></span><span style="font-family:"font-size:16px;">The grounding isolation strip near the crystal oscillator must be well grounded.</span><span style="font-family:"font-size:12pt;mso-spacerun:"mso-fareast-font-family:宋体;mso-font-kerning:1.0000pt;"></span> </p><!--EndFragment-->

50

comment

All comments

Unknown

Unknown

3492

0

50

Rules about cashback: 1. Valid time: ALLPCB cashback activity will end on April 1st. 2. Capped amount: The capped amount of cashback for each account is $5,000. Each order can get a maximum of $2,000 cashback. That means every author can get $5,000 max. 3. Cashback range: The cashback activity only covers the corresponding PCB order. The order amount for other combined payment products will be invalid. 4. Clicking your own promotional link will be invalid. The same email address, shipping address, contact information, and phone number are all recognized as the same account. 5. ALLPCB has the final interpretation right of the cashback activity.

ALLPCB will donate 2% to the author for this promotion link.